Introduction to Machine Vision in Manufacturing

Step into the world of modern manufacturing, and you’ll find a fascinating transformation unfolding. At its heart? Machine vision—the cutting-edge fusion of visual perception and technology. Picture this: machines with eyes so sharp they can inspect, sort, and measure faster than any human ever could. It’s like giving your production line a superpower.

Why Machine Vision Feels Like a Game-Changer

Imagine the tedious, manual inspections that factories once relied on—slow and often prone to human error. Enter machine vision, a technology that blends cameras, sensors, algorithms, and AI to perform these tasks seamlessly. From detecting microscopic flaws on circuit boards to verifying product labels at lightning speed, it’s all about precision and perfection.

What makes it even more exciting is the adaptability. A system that inspects car parts today can switch to monitoring food packaging tomorrow with just a few tweaks. It’s like having a shapeshifting superhero in your manufacturing toolkit.

- High-speed cameras: capturing every detail in milliseconds.

- AI-powered software: learning and improving inspection accuracy over time.

- 3D imaging: analyzing depth and dimensions with pinpoint accuracy.

Real-Life Magic on the Factory Floor

Take the tire industry, for example. With machine vision, manufacturers can spot bubbles or inconsistencies invisible to the naked eye, ensuring every tire rolling off the line is roadworthy. Or consider pharmaceutical companies using it to verify that every pill in a blister pack is perfectly placed. These aren’t just efficiencies—they’re lifesaving standards.

Machine vision doesn’t feel robotic; it feels revolutionary. It’s not replacing humans—it’s empowering them, taking care of repetitive tasks and letting people focus on creativity and innovation. That’s manufacturing reimagined!

Key Technologies Driving Machine Vision Systems

The Smart “Eyes” Behind Machine Vision

Let’s take a moment to appreciate the unsung heroes of machine vision systems—the technologies that act as their sharp, tireless eyes. At the heart of it all are **cameras**, but don’t mistake these for your average point-and-shoot. These are precision instruments that capture every microscopic detail of a product on an assembly line, identifying flaws faster than a hawk spotting its prey. From monochrome to 3D imaging, these cameras bring extraordinary clarity to the task.

Then there’s the brainpower—**image processing algorithms**. Think of them as puzzle masters, swiftly interpreting visual data and making decisions with lightning speed. Combine this with high-powered **processors**, and you’ve got a vision system that doesn’t just see, but understands what it’s looking at.

- Deep learning: Ever heard of machines teaching themselves? Deep learning algorithms help vision systems improve their accuracy over time, just like humans sharpening their skills.

- Lighting systems: The unsung storyteller! Proper lighting enhances features or flaws on a product, ensuring no imperfection escapes unnoticed.

Together, these technological marvels form a symphony of intelligence, precision, and speed, turning ordinary machines into diligent inspectors.

Applications of Machine Vision in Product Manufacturing

Transforming Quality Control with Precision

Picture this: a production line humming with activity, each product whizzing past as if choreographed, while an eagle-eyed inspector misses absolutely nothing. That inspector? It’s not human—it’s a machine vision system, armed with accuracy no human could dream of. These systems are reshaping the core of quality control.

With cameras and algorithms working together, machine vision doesn’t just “see” defects—it eradicates them before they reach your customers’ hands. Scratches on smartphone screens, microscopic flaws in circuit boards, misaligned labels on bottles—these imperfections stand no chance against its scrutiny.

Key applications include:

- Defect Detection: Spotting surface abnormalities, dents, or cracks instantly.

- Assembly Verification: Ensuring every piece fits like a puzzle before shipping out.

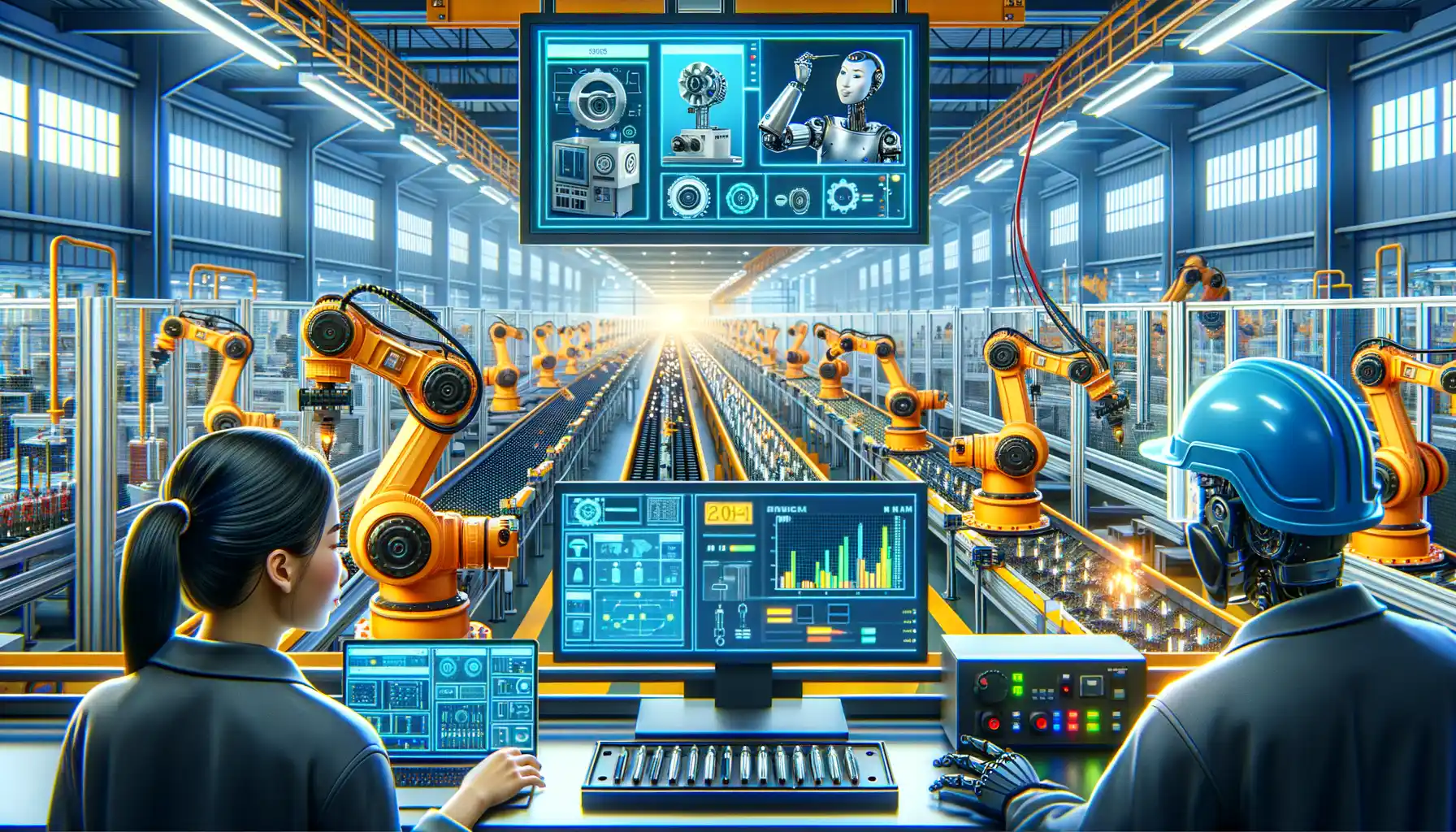

Robotic Guidance: Eyes for the Machines

Imagine robots assembling products with the precision of a master jeweler. How? Machine vision serves as their “eyes.” By interpreting visual data, it guides robotic arms to position parts, screw in bolts, or even weld seams perfectly every time. This technology isn’t just improving efficiency—it’s elevating manufacturing to an art form.

From automotive assembly lines to delicate electronics production, machine vision ensures every move is precise, swift, and flawless. With such a tool, perfection isn’t just attainable—it’s automatic.

Benefits of Machine Vision for Manufacturing Efficiency

Transforming Efficiency: Why Machine Vision Is a Game-Changer

Step into the manufacturing world and picture this: a tireless, eagle-eyed assistant inspecting every product with pinpoint precision, never blinking or missing a beat. That’s what machine vision systems bring to the table. They’re not just tools; they’re partners in perfection, supercharging your production lines in ways you didn’t think possible.

Here’s where the magic happens:

- Unbeatable speed: Machines don’t get tired, distracted, or bored. They can inspect thousands of parts per minute, shaving precious seconds off every process.

- Laser-sharp accuracy: Forget human error. Machine vision detects flaws invisible to the naked eye—a tiny crack, a slight misalignment, or even color variations—catching them before they wreak havoc on production.

- Cost efficiency: With fewer mistakes and faster quality checks, you save big on rework, waste, and downtime. It’s a win-win for your budget and bottom line.

A Tailor-Made System for Every Demand

Whether it’s ensuring perfectly sealed bottles or spotting micro-defects in circuit boards, machine vision adapts seamlessly to your specific needs. Take automated assembly lines, for example: these systems integrate flawlessly, checking measurements, guiding robotic arms, and ensuring everything runs like clockwork.

Imagine your team focusing on innovation and strategy while your machine vision system handles the grunt work tirelessly. That’s the future of manufacturing—a partnership between human creativity and machine precision, driving efficiency to extraordinary new heights.

Future Trends and Innovations in Machine Vision

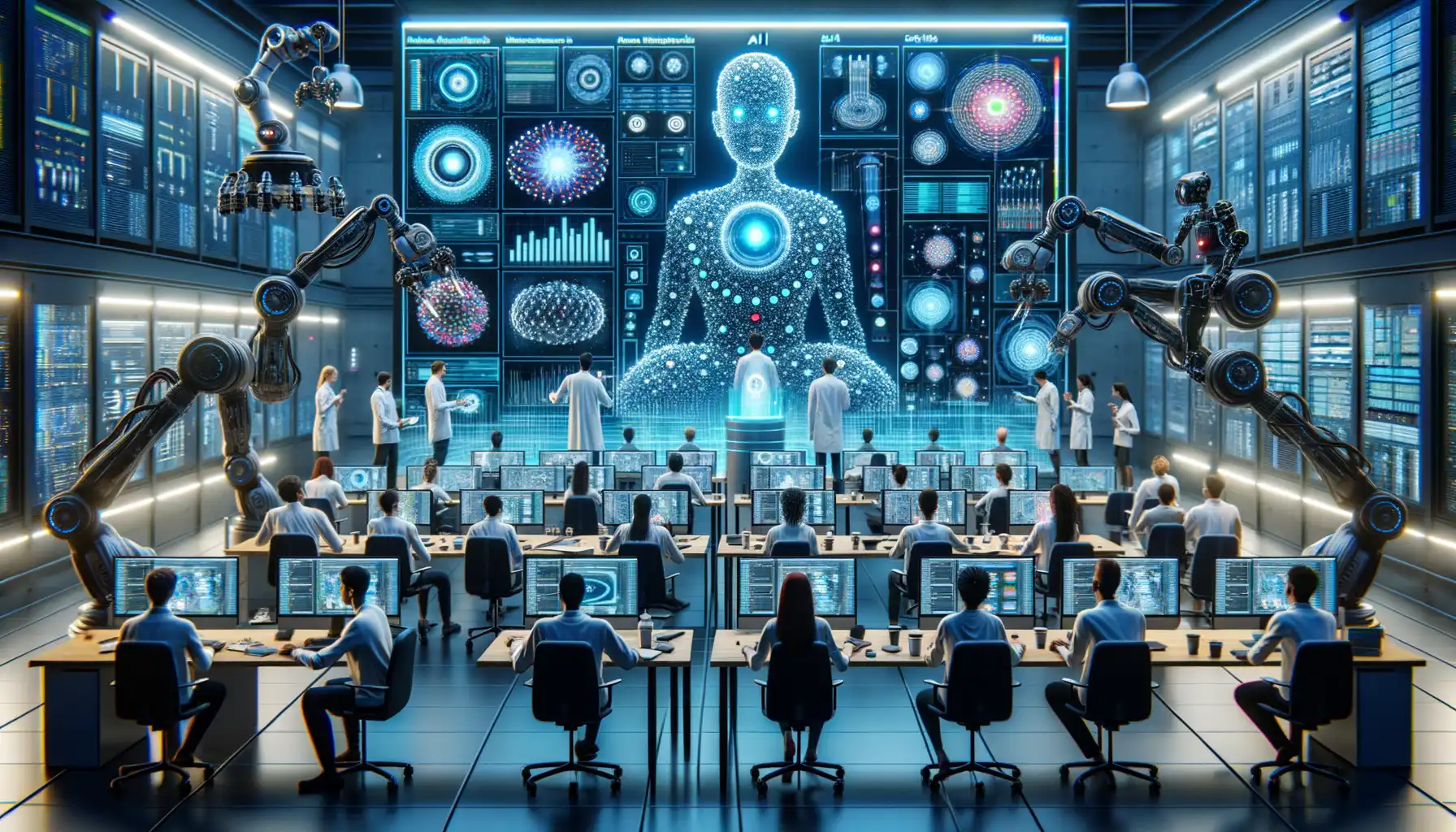

New Frontiers: The Rise of AI-Powered Vision

Imagine a machine with eyes that not only see but think—this is where we’re headed. Thanks to the unstoppable march of AI and deep learning, machine vision is transforming before our eyes. These systems no longer just detect flaws; they predict them, preventing production issues before they even occur. It’s like giving your assembly line a crystal ball.

Look out for trends like:

- Edge computing: Cameras equipped with processing power, analyzing data on the spot faster than ever.

- Multi-spectral imaging: Machines now see beyond human capabilities—including ultraviolet and infrared—to uncover hidden details.

From identifying subtle color variations in food to spotting microscopic cracks in aerospace parts, these advancements push boundaries daily. What was futuristic yesterday is just routine today.

Collaborative Vision: Machines That Learn With Us

The future isn’t about machines replacing humans—it’s about working together. Machine vision systems are becoming more intuitive, adapting to unique workflows. Think augmented reality-style overlays showing workers exactly where repairs are needed, or robots learning from human input like apprentices mastering their craft.

With innovations like digital twins, manufacturers can simulate entire production lines virtually, pairing vision systems with real-world data to refine processes. This synergy turns manufacturing into a living, breathing ecosystem of efficiency and imagination.